Details

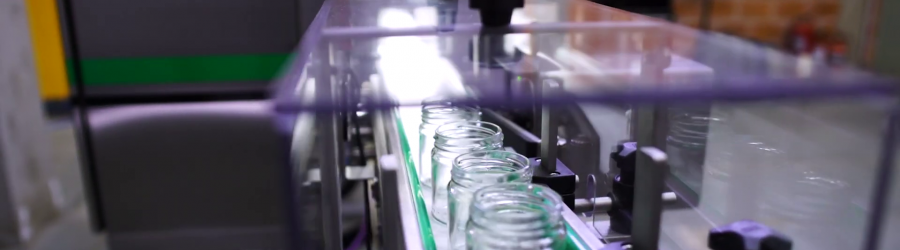

Inspection machine for glass jars according to the plan mentioned in the specification through the use of vision cameras Omron, with a rate of 55 Bottles/minute through a single line of work. Entry and exit to the system by means of a conveyor belt with the bottles face up.

5 mm is the ideal minimum surface of the object to be detected with a discard of 3 to 5%.

Tests were carried out with an Omron vision system with 2 cameras and it was concluded that the system can detect particles of 3 to 4 millimeters but with a progressive rejection of more than 45% as the size of the particle decreases. Below 3 millimeters the discard is total.

The inspection station is fully automatic, made up of 2 Omron vision equipment that detects both metal particles and glass fragments.

It consists of a conveyor belt, which moves the bottles with the appropriate separation (approximately 35 mm) and at a line speed of 55 bottles/minute.

It is placed in the first instance in station 1, for glass inspection. Then, next to it, is station 2, where in this case it is inspected that the bottle does not contain other types of foreign particles.

When the vision systems detect metallic particles, glass fragments or any other object inside a bottle that should not be in it, it gives the corresponding warning and the bottle is discarded from the line.