Details

The work consisted of mechanical and programming reforms in a cheese cutting machine, bringing its current rate from 470 lasts/hour to 750 lasts/hour.

The main characteristic consists of taking advantage of the “dead” time of the equipment that is generated when the wedge returns to look for the cheese and waits, while the second half is rotated, on the same exit channel.

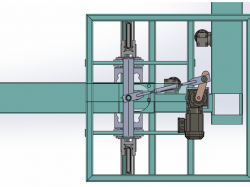

Electric cylinders were replaced by a motorized system, through a conventional motor and a mechanical crank-rod system, which allows the forward and reverse movement of the machine through a control by means of a frequency variator.

Summary of the provision:

- Complete relief of the team.

- Engineering and design of new parts.

- Construction of new necessary parts.

- Mechanical reform of the machine itself in our facilities.

- Change of technology in advance step of machine.

- FAT tests in our workshops.

- Installation, assembly and PEM.

Also carried out:

- PLC and panel program reforms.

- Plans of new parts to install on the machine.

- Electrical planimetry of the reforms.