Details

Technological update in dairy plant including engineering for the new development, generation of new control programs and reconditioning of operating panels and boards. Operators were also trained and electrical plans and programs were delivered..

Issues:

- Operation with errors and without continuity.

- Control with almost obsolete logic.

- Production stops due to failures.

- No possibility to record data and alarms.

- No communication with the rest of the plant

- No technical support from the manufacturer.

- Lack of spare parts.

Solutions:

- Replacement of obsolete technology.

- Increased reliability associated with new technology.

- Precise control of very sensitive parameters.

- Data register.

- Real-time monitoring to control, manage and improve equipment efficiency.

- Minimum investment

- Se adaptaron los trabajos a la parada de planta anual por mantenimiento.

Works done

- Transportation of powdered milk to storage silos: Replacement of PLC SLC 5/02 Allen Bradley by a Siemens ET200, achieving distributed periphery connected to Siemens PLC belonging to evaporators. Migration of programs due to brand change. Integration of the system to the existing SCADA.

- Transfer from powdered milk to fractionated: Replaced SLC 5/02 PLC with a new Allen Bradley CompactLogix 5370. Removed old RIO communication with plant system and replaced with Ethernet IP. Integration of the transport system in the existing operating panel.

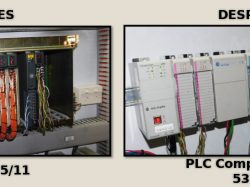

- Cartesian bag palletizer: Replaced SLC 5/11 PLC with a new Allen Bradley CompactLogix 5370. Added 10" operating panel (Replaced existing dedicated PC). A 100% new program was developed with migration of palletizing recipes from PC to Panel.