Details

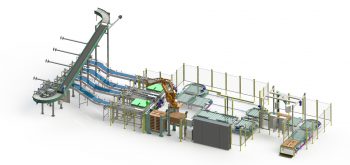

The proposal includes calculation engineering, design, manufacturing and assembly of a fully automatic palletizing system with the possibility of being manufactured in stages in order to allow the interested party to plan investments. All automation is done on the basis of a anthropomorphic robot ABB IRB 660 and its main objective is to orderly palletize the packs with packages of yerba coming from the packing room on an arlog-type pallet of standardized size (1×1, 2m).

Final position: complete and wrapped pallets on roller table for transfer to the stored sector by means of forklifts.

The automation also contemplates the conveyors and transfers necessary to identify the different types of flavors and presentations identified by barcode and divert them to the different conveyors, sending them to the position of being taken for palletizing.

Packs of 500g and 1kg of yerba, from 4 packaging lines with different flavors. Due to the aforementioned, it is palletized in 4 different stations; today 14 pallets per hour are being made. Putting this system into operation reduced operating costs by 80%.

Layout 3D